Introduction

Water is a precious resource, and the importance of proper Industrial waste water filtration systems cannot be overstated. In industrial applications, where large volumes of water are used and contaminated, effective filtration systems play a crucial role. This blog will delve into the benefits, Industrial waste water filtration systems opportunities for sustainable and innovative approaches, different types of filtration systems, and the significance of various strainers used in Industrial Water Treatment.

Benefits of Filtration in Industrial Applications

- Improved Product Quality and Consistency: Filtration systems remove impurities and contaminants, resulting in higher quality and more consistent products.

- Enhanced Equipment Performance and Longevity: Clean water reduces scaling, corrosion, and clogging, prolonging the lifespan and efficiency of industrial equipment.

- Compliance with Regulatory Standards and Environmental Protection: Filtration ensures that wastewater meets regulatory requirements, protecting the environment and safeguarding public health.

- Cost Savings through Reduced Maintenance and Downtime: Efficient filtration systems minimize equipment breakdowns, maintenance costs, and production interruptions.

Opportunities for Sustainable and Innovative Approaches in Filtration

Sustainable filtration practices offer long-term benefits for both businesses and the environment. Some opportunities to explore include:

- Adoption of Advanced Filtration Technologies: Innovations such as membrane filtration, electrochemical filtration, and nanotechnology enable more efficient removal of contaminants.

- Recycled Water Applications: Implementing filtration systems that facilitate water recycling reduces freshwater consumption and waste generation.

- Energy Optimization: Incorporating energy-efficient filtration technologies and optimizing filtration processes contribute to sustainability goals.

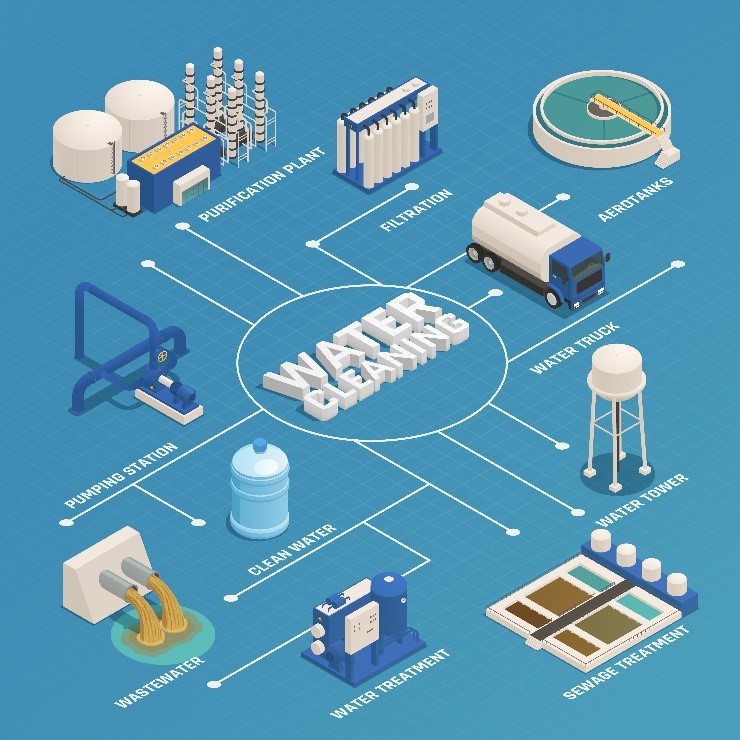

Types of Industrial Filtration Systems

Industrial wastewater filtration systems encompass various types, each with specific applications and benefits:

- Mechanical Filtration: Utilizes physical barriers like screens, cartridges, and media filters to trap suspended solids and larger particles.

- Chemical Filtration: Involves the use of chemical agents, such as activated carbon or ion-exchange resins, to remove dissolved contaminants.

- Biological Filtration: Harnesses natural microorganisms to break down organic matter and remove pollutants through biological processes.

Types of Strainers in Industrial Filtration

Strainers play a vital role in removing larger particles from industrial wastewater. Common types include:

- Basket Strainers: Feature a basket-like design with a mesh or perforated plate to capture debris and solids.

- Cartridge Strainers: Use replaceable cartridges made of pleated fabric, mesh, or porous materials to remove particulate matter.

- Bag Filters: Utilize fabric or synthetic bags to trap contaminants, offering a cost-effective solution for high-flow applications.

Considerations for Selecting and Implementing Filtration Systems

When choosing and implementing filtration systems, it is essential to consider several factors:

- Water Quality and Contaminant Profile: Understanding the specific contaminants present helps select the appropriate filtration technology.

- Flow Rate and Capacity: Sizing the filtration system correctly ensures optimal performance and prevents bottlenecks.

- Maintenance and Operational Requirements: Evaluating maintenance needs, required expertise, and system longevity aids in choosing a suitable solution.

- Compliance and Regulations: Ensuring the filtration system meets regulatory standards is crucial for legal compliance and environmental responsibility.

FAQ

What are the Opportunities for Sustainable and Innovative Approaches in Industrial Filtration?

Opportunities for sustainable and innovative approaches in industrial filtration include:

- Adoption of advanced membrane technologies

- Integration of biological treatment methods

- Utilization of renewable energy sources

- Water reuse and resource recovery initiatives

What are the different types of Industrial Filtration Systems?

Different types of industrial filtration systems:

- Mechanical filtration systems use physical barriers like screens and cartridges.

- Chemical filtration systems involve chemical agents for contaminant removal.

- Biological filtration systems rely on microorganisms to break down pollutants.

- Membrane filtration systems use semipermeable membranes to selectively remove particles and dissolved substances.

How do industrial filtration systems contribute to achieving regulatory compliance and meeting environmental standards?

Industrial filtration systems contribute to achieving regulatory compliance and meeting environmental standards by:

- Removing pollutants and contaminants from wastewater, ensuring that discharged water meets regulatory limits and guidelines.

- Implementing filtration technologies that specifically target regulated contaminants, such as heavy metals or organic pollutants, to meet specific regulatory requirements.

How does the selection of the appropriate filtration system impact the quality of the treated water in industrial applications?

The selection of the appropriate filtration system impacts the quality of treated water in industrial applications by:

- Ensuring the removal of specific contaminants based on the system’s design and capabilities.

- Optimizing filtration efficiency and effectiveness, resulting in higher-quality treated water.

- Meeting the required water quality standards for specific industrial processes or applications.

How do you Filter Industrial Waste Water?

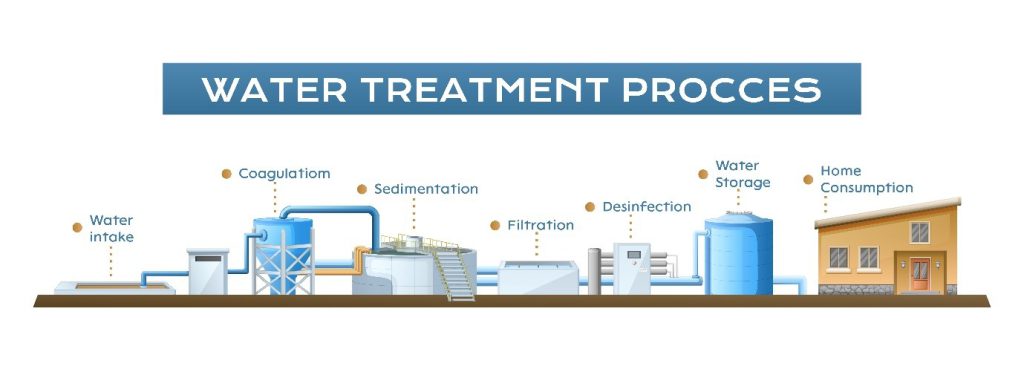

Industrial wastewater can be filtered through several methods including physical, chemical, and biological processes. Common techniques include sedimentation, filtration, chemical precipitation, coagulation, flocculation, activated carbon adsorption, and membrane filtration.

What is the Best Waste Water Treatment Method?

The best wastewater treatment method depends on the specific contaminants present and the desired level of purification. There is no one-size-fits-all solution. However, advanced treatment processes such as activated sludge, reverse osmosis, and advanced oxidation processes (AOPs) are often considered effective for removing a wide range of pollutants.

What are the 4 types of Purification used in Waste Water Treatment Plants?

The four types of purification commonly used in wastewater treatment plants are:

- Preliminary Treatment: This involves the removal of large objects and debris through physical processes such as screening and grit removal.

- Primary Treatment: It focuses on the removal of settle able solids and suspended organic matter through processes like sedimentation and flotation.

- Secondary Treatment: It utilizes biological processes to break down organic matter and remove dissolved contaminants. Common methods include activated sludge, trickling filters, and oxidation ponds.

- Tertiary Treatment: This stage involves advanced treatment processes to further remove remaining pollutants. Methods like filtration, disinfection (e.g., chlorination or ultraviolet light), and chemical precipitation are employed.

What are the Methods of Waste Water Filtration?

Some methods of wastewater filtration include:

- Sand Filtration: In this method, wastewater is passed through a bed of sand to remove suspended particles and some microorganisms.

- Activated Carbon Filtration: Activated carbon adsorbs organic compounds, odours, and some heavy metals, improving the water quality.

- Membrane Filtration: This technique employs membranes with tiny pores to physically filter out particles, microorganisms, and dissolved substances.

- Biological Filtration: Certain types of bacteria and microorganisms can break down organic pollutants in wastewater through biological processes such as bio filtration or bioremediation.

Conclusion

In conclusion, Industrial wastewater filtration systems are essential for achieving sustainability, efficiency, and regulatory compliance in various industries. Importance of Industrial Wastewater Treatment By implementing the right filtration systems and adopting innovative approaches, industries can enhance product quality, protect the environment, and reduce operational costs. Furthermore, the processes of Coagulation and Flocculation in wastewater treatment play a crucial role in effectively removing contaminants and ensuring the overall success of the treatment process.

With a focus on responsible and efficient wastewater management, industries can pave the way for a greener and more sustainable future, with Hpi Pro’s team of experts by their side. Hpi Pro have a team of experienced professionals who can offer the required technical assistance and expertise.