Introduction

Industrial process tanks play a pivotal role across diverse sectors, serving as essential containers for the storage, processing, and transportation of liquids and chemicals. Their significance lies in facilitating efficient and controlled handling of substances critical to processes in industries such as manufacturing, chemical processing, power generation, and more.

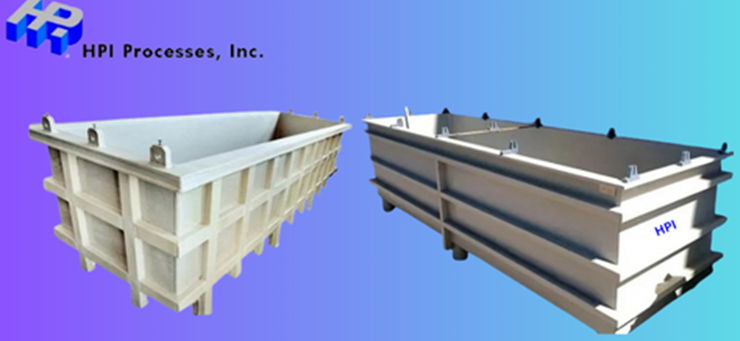

Polypropylene tanks stand out as a versatile solution in the realm of industrial storage and processing. Composed of a lightweight yet durable material, these tanks offer a unique combination of properties that make them suitable for a wide array of applications. Their versatility extends across industries like chemical processing, water treatment, power generation, and beyond. In this blog, we will delve into the distinctive characteristics of Polypropylene Tanks.

Polypropylene Tanks: A Material Overview

Unique Properties Suitable for Industrial Use:

- Chemical Resistance This property ensures the integrity of the material, even in the presence of aggressive chemicals.

- Lightweight Nature: One of the defining features of polypropylene is its low density, contributing to its lightweight nature. This characteristic facilitates ease of handling, transportation, and installation of Polypropylene Tanks, making them practical and efficient for various industrial processes.

- Highly Durable: It can withstand physical stress, impact, and environmental factors, ensuring a long lifespan and reliability in demanding industrial settings.

- Temperature Tolerance:. This allows it to function effectively in applications involving both low and high temperatures, enhancing its adaptability to diverse industrial processes.

- Versatility in Fabrication:. This makes it a flexible material for manufacturing various types of industrial containers, including tanks tailored to specific requirements.

Benefits of Polypropylene tanks

Polypropylene storage tanks offer distinct advantages over their stainless steel counterparts.

Firstly, plastic, often unfairly criticized due to pollution issues, is a versatile material ideal for industrial use. Unlike stainless steel, plastic doesn’t break; instead, it bends and deforms.

Cost-effectiveness is another significant advantage of PP tanks over steel. Plastic is as effective as steel in containing liquids but is considerably cheaper to manufacture, enabling quick production and scalability for businesses.

Maintenance of polypropylene storage tanks is more straightforward, with the option to establish self-cleaning systems. This ease of maintenance contributes to the overall superiority of PP tanks over stainless steel in active storage applications.

Polypropylene vs. Polyethylene Tanks: What’s the Difference:

People often associate plastic with a single material, but there are numerous types of plastics, each with distinct characteristics. This diversity becomes crucial when choosing a plastic tank for various applications, especially for holding liquids. Among the common options are polypropylene (PP) and polyethylene, each offering unique benefits.

- Practical Differences: Practical considerations outweigh chemical differences. Polyethylene handles higher temperatures than polypropylene, making it suitable for a broader range of applications. However, polypropylene excels in durability, with high-impact resistance and stress resilience, making it preferable for applications prioritizing robustness.

- Chemical Differences: Understanding the chemical makeup of plastics is essential. While polypropylene and polyethylene share similar chemical compositions, their use of different monomer units in processing creates significant variations. Polyethylene relies on ethylene monomer units, while polypropylene uses propylene monomer units, resulting in distinct features.

- Melting Point: Polyethylene generally has a higher melting point than polypropylene, but both can withstand various temperatures depending on the specific blend. Polyethylene is more adept at handling extreme temperatures.

- Plastic Durability: Polypropylene is known for superior durability, particularly in terms of impact resistance and stress endurance. While polyethylene is also durable, it doesn’t specialize in high-impact scenarios like polypropylene.

- Chemical Resistance: In chemical resistance, crucial for tank applications, polypropylene holds an advantage. It can resist a broader range of organic solvents, chemicals, and acids compared to polyethylene, making it the preferred choice for corrosion-resistant tanks.

- Weight: Considering raw plastic density, polyethylene is significantly lighter than polypropylene. The lighter weight of polyethylene makes it easier to move and handle, a crucial factor for tanks intended for mobility.

- Production Costs: Polypropylene stands out as the less expensive material for plastic items. While the choice should align with the tank’s functionality, being aware of the cost difference is essential for budget considerations.

- Recycling the Plastic: Polyethylene is easier to recycle into other products, making it a preferable choice for those considering environmental impact. However, it is resource-intensive, emits carbon dioxide, and degrades slowly in landfills.

Applications :

Polypropylene tanks find extensive use across various industries due to their versatile and durable nature.

- Chemical Processing:

Polypropylene tanks excel in chemical processing applications, providing excellent resistance to a wide range of chemicals. Their corrosion-resistant nature makes them crucial for safely storing and handling various chemical substances.

- Water Treatment:

In water treatment facilities, Polypropylene Tanks are employed for their resistance to corrosion and the ability to handle liquid temperatures effectively. They play a crucial role in storing and processing water in different treatment stages.

- Power Generation:

Polypropylene tanks play a vital role in power generation applications, where they are utilized for storing and processing liquids associated with power plant operations. Their durability and resistance to corrosion contribute to reliable performance.

- Oil and Fuel Processing:

Polypropylene tanks are employed in the oil and fuel processing industry for their ability to withstand the demands of storing and processing different types of oils and fuels. Their durability ensures safe and reliable containment.

Conclusion :

Polypropylene Tanks prove invaluable across industries, offering durability and chemical resistance. When it comes to reliable solutions, HPI Processes is your ultimate destination for comprehensive industrial solutions As a one-stop solution for process lines and tanks, we invite you to explore our products. Disscuss your application today.